7 Best Roofing Plywood: OSB vs Plywood

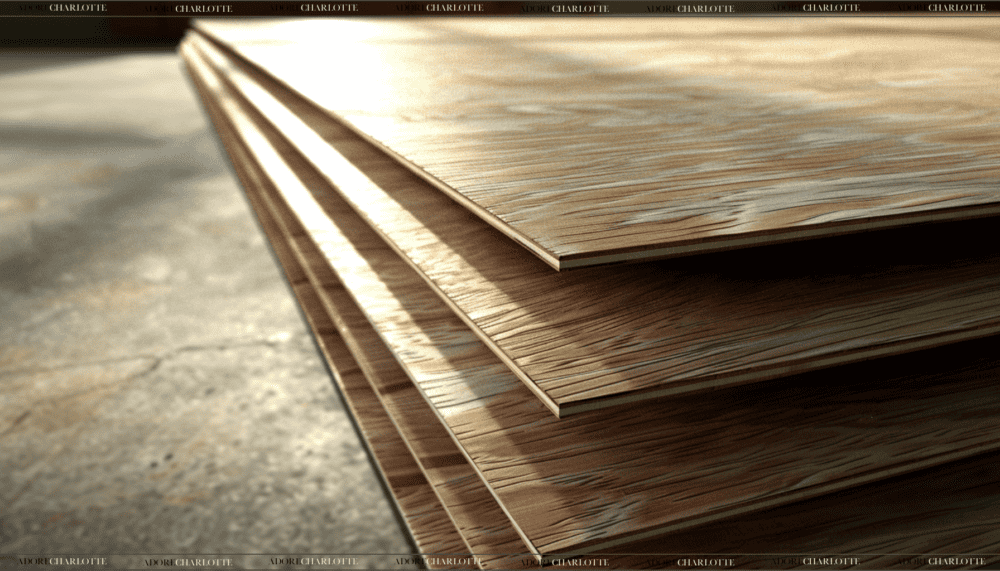

Have you ever wondered what lies beneath the shingles of your home’s roof? The answer might surprise you. Since owning my home, I have become deeply intrigued by the nuances of home construction. I’ve unearthed some interesting insights on plywood and OSB (Oriented Strand Board). The two major factors in the realm of roofing when selecting the best roofing plywood for your home.

It’s important to familiarise yourself with the building code and the different types of plywood to make an informed decision. But how do you sift through the technical jargon to discover the most durable, cost-effective, and suitable plywood?

Don’t worry; I’ve done that for you. I feel like a pro regarding plywood and what’s needed to get the best for your roof and building structure. In this article, I’ve broken down everything you need to know about the different types of Plywood and OSB. What defines the best roofing plywood? The pros and cons, and comparisons.

Key Takeaways

- Decode the fundamental differences between plywood and OSB (Oriented Strand Board) and how they respond to moisture.

- Understand the importance of choosing the best plywood that complies with building codes while fitting your specific roofing requirements.

- Learn why OSB has become such a popular choice for roofing despite the traditional preference for other plywood types.

- Evaluate the strengths of plywood for its stability and quick-drying capabilities versus OSB’s cost-effectiveness and consistent performance under damp conditions.

- Discover the impact of moisture resistance and ease of access to supplies of plywood for your roof replacement endeavour.

Understanding Plywood and OSB in Roof Decking

Choosing the right materials for roof decking is essential to ensure the durability and integrity of the structure. Whether you’re embarking on a new roofing project or replacing existing materials, comprehensive knowledge of available options is key.

As you may know, we moved into our beautiful home in Essex from London at the end of 2022. We’ve been on a slow path to getting things just as we want, on the right budget. Our home decor has been at the forefront of our list, followed by the major renovation. Well, apart from our winter boiler replacement blip last year.

This includes our back garden patio area roofing. We are still in two minds about what we plan on doing. Keeping the wood beam pillars, adding a roof and asphalt shingles or getting rid altogether. Starting from scratch with a whole new design, there are many options for us to choose from. The world is our oyster, as they say.

What Defines the Best Roofing Plywood

When it comes to roofing plywood, the quality of the material dictates its suitability for different roofing applications. Factors like moisture resistance, layers of wood, load-bearing capacity, and environmental conditions guide my recommendations.

The use of plywood is widespread; its cross-laminated construction ensures stability and resilience. This makes it an excellent choice for internal structures where the conditions are controlled. Yet, for external use, especially roofing, you must consider the material’s reaction to prolonged exposure to moisture.

The Importance of Decking Material Choice

Every roofing project demands materials that can withstand its own unique challenges. The strength of the roof decking is fundamental to the overall structural stability of the roof. OSB is often considered one of the best roofing choices. Its compressed wood chip composition gives an impressive performance in moisture-heavy conditions.

Its affordability makes it particularly attractive for large projects, while its performance tops the list for use in subfloors. Unfortunately, If your home is based in the UK, this may not be true due to moisture factors.

According to Planted Material, OSB is not waterproof or water resistant. Like most wood-based materials, OSB expands and contracts as moisture is wicked into and expelled from wood fibres. As you know, the UK weather frequently gives us the most pleasant showers.

Its suitability for roofing in very wet climates or areas with high moisture may require additional considerations. Proper ventilation and moisture barriers are highly important to prevent potential issues such as swelling.

Roofing projects in climates like the UK’s

WBP (Water and Boil Proof) Plywood and Marine-Grade Plywood stand out as superior choices for roofing projects in climates like the UK. Where moisture is a significant concern, WBP Plywood is specifically designed for high moisture resistance. Making it ideal for roofing applications where exposure to rain is frequent.

Marine-Grade Plywood offers the highest level of water resistance due to its construction with waterproof glues and high-quality wood. This ensures durability even in very wet conditions, making both options provide the necessary protection against moisture. This, in turn, enhances the roof’s longevity and structural integrity.

Plywood, where moisture isn’t a significant concern

CDX Plywood is a solid choice. CDX stands for “C-D Exposure 1 plywood” and is commonly used in the construction industry for its durability and cost-effectiveness. The “CD” refers to the veneer grades on the plywood sheet’s front and back.

While “X” indicates that the glue used in the plywood is exterior grade which can withstand temporary exposure to moisture. CDX Plywood is preferred for its strength and affordability, making it suitable for various construction projects. This includes roofing underlayment where prolonged exposure to moisture is not expected.

Short-term roofing solutions & structural plywood

Materials like shuttering ply can be utilised effectively for temporary structures or construction areas requiring short-term roofing solutions. These scenarios often require a quick, economical cover to protect against immediate environmental factors, not long-term durability.

In such cases, selecting roofing material prioritises ease of installation, removal, and cost-efficiency over long-term weather resistance. Proper treatment or temporary waterproofing measures should be considered to ensure adequate protection during construction.

Plywood vs OSB: Composition and Use in Construction

The debate between OSB and plywood is an ever-present topic among professionals in the construction industry. In examining the composition and usage of these materials, it’s essential to highlight their distinct differences.

Plywood’s ability to face high moisture levels makes it an exceptional roofing material. While OBS, with its traditional woodchip layers, offer familiar workability and ease of use.

However, in my opinion, the specifics of the construction project will ultimately dictate the best choice. Whether it be OSB or another quality roofing plywood variant.

| Plywood Type | Cost-Effectiveness | Durability | Moisture Resistance | Rot & Insect Resistance | Fire Resistance | High-Quality Construction |

|---|---|---|---|---|---|---|

| CDX Plywood | High | Good | Moderate | No | No | No |

| OSB | High | Good | Moderate | No | No | No |

| Shuttering Plywood | Moderate | High | Moderate (with treatment) | No | No | Moderate |

| WBP Plywood | Moderate | High | High | No | No | Moderate |

| Pressure-Treated Plywood | Low | High | High | Yes | No | No |

| Marine-Grade Plywood | Low | Very High | Very High | Very High | No | Yes |

| Fire-Rated Plywood | Low | High | Moderate | No | Yes | Moderate |

Moisture Resistance and Durability: A Comparative Analysis

As we delve into the performance of roofing materials, particularly OSB and plywood, it’s crucial to scrutinise these materials. A significant factor for homes across the UK is moisture. Looking at how each material reacts to moisture is important. When selecting the best material for roof decking, understanding their capacity to resist water and remain durable over time becomes paramount.

Water Infiltration: How Plywood and OSB React

My research has revealed that plywood, traditionally used in roofing, offers satisfactory moisture resistance for temporary wet conditions but is susceptible to degradation if soaked continually.

It is not inherently the most long-lasting choice unless subjected to pressure treatment like the Pressure-Treated plywood. Contrarily, OSB, due to its manufacturing of compressed wood chips and resin, presents an incredibly robust barrier against water infiltration, crucial for regions prone to extreme weather. Both materials require proper installation and treatment for optimal performance in wet conditions.

Longevity Concerns under Damp Conditions

Regarding the longevity of roofing materials, both types of wood have their own advantages and disadvantages. Some Plywoods, like Marine-grade plywood and WBP (Water and Boil Proof) plywood, may excel in quick drying and are less likely to succumb to water damage in the short term. However, for long-standing resilience, OSB typically takes the lead. Nevertheless, its tendency to expand when wet must be factored into any decision involving roofing materials.

Through my hands-on experience and detailed analysis, the worth of each plywood variation becomes clear. It’s not just about picking the best of the two but choosing the most apt for your circumstances. Whether building a new home or renovating an old roof, proper knowledge of the materials available is indispensable in constructing a safe and lasting home.

| Plywood Type | Pros | Cons |

|---|---|---|

| CDX Plywood | Affordable, durable, and suitable for exterior use with proper sealing. | Rough surface, not ideal for visible finishes. |

| OSB (Oriented Strand Board) | Cost-effective, strong, and widely used in construction. | Swells with moisture, less aesthetically pleasing. |

| Shuttering Plywood | High load-bearing, ideal for concrete formwork. | Not for aesthetic applications, it requires moisture treatment. |

| WBP Plywood | Excellent moisture resistance, durable for exterior use. | It is more expensive than CDX and OSB. |

| Pressure-Treated Plywood | Resistant to rot, insects, and moisture. | Chemical treatments may raise health concerns and be more expensive. |

| Marine-Grade Plywood | Superior moisture and rot resistance, high-quality. | It is significantly more expensive and may be overkill for some projects. |

| Fire-Rated Plywood | Increased resistance to fire and meets specific safety codes. | It is more expensive and may not be necessary for all projects. |

Cost-Benefit Considerations for Your Roofing Project

When faced with a roofing project or roof repairs, my initial step is to weigh the cost-benefit of the materials on offer. Across the UK, homeowners and contractors continually seek affordable roofing materials that don’t sacrifice quality for the price. In this context, OSB emerges as a compelling contender, known for being budget-friendly without compromising the ability to support heavy loads.

CDX plywood may appeal to those of us who have a little more flexibility in our budget and favour materials with superior dimensional stability with different sizes, even though it comes with a higher price tag.

CDX plywood is traditionally the material of choice for those who require a product that can take on variable conditions but may incur greater costs over time if not maintained properly.

In the realm of affordable plywood for roofing, CDX plywood often emerges as the most cost-effective option. It balances cost and durability, making it a favoured choice for sheathing and subflooring tasks. Plywoods can endure temporary exposure to moisture, coupled with lower price points compared to speciality plywoods like marine-grade or pressure-treated options.

| Material | Cost Effectiveness | Size Variability | Load Bearing Capacity | Dimensional Stability |

|---|---|---|---|---|

| OSB | High | Limited | High | Moderate |

| CDX Plywood | Moderate | Good | High | High |

| Marine-Grade Plywood | Low | Good | Very High | Very High |

| Pressure-Treated Plywood | Moderate | Good | High | High |

| WBP Plywood | Moderate | Good | High | High |

| Shuttering Plywood | Moderate | Limited | High | Moderate |

The best choice is based on individual needs, the project’s scale, and the specific demands on roofing materials. Whether I opt for OSB or CDX plywood for my projects, I will always ensure it aligns with what my project prioritises: affordability, durability, load resistance, or stability through the seasons.

The Environmental Impact of Roofing Materials

As I delve into the building and construction domain, a considerable aspect of my investigation pertains to the environmental impact of our choices. It’s a responsibility that we, as conscious builders and homeowners, carry—selecting sustainability in the materials we employ has far-reaching consequences for our planet.

Sustainability of Wood Sources

The timber used to create roofing materials is a critical starting point. Traditional plywood manufacturing has long relied on establishing trees, which affects our environment. Yet, it’s heartening to see that the wood industry has taken remarkable steps towards creating a green footprint with initiatives that endorse sustainable forestry practices. A noteworthy change is significantly reducing old-growth tree harvesting to mitigate deforestation.

Plywood Manufacturing and the Ecology

It’s also essential to consider the ecological nuances of plywood production. Historical uses of chemicals like formaldehyde in adhesives raised concerns over indoor air quality and the broader environmental impact.

However, material science strides offer us fresh air—advancements that reduce emissions and enhance plywood’s green building material status. This progression ensures that when I decide on materials, I am not just constructing roofs but supporting a healthier ecosystem.

| Material | Source of Wood | Renewability | Sustainable Practices | Environmental Impact |

|---|---|---|---|---|

| OSB | Fast-growing trees, wood waste | High | Efficient use, minimal waste | Moderate, depends on glue |

| CDX Plywood | Softwood trees | Moderate | Varies by source; some certified sustainable | Moderate, depends on forestry practices |

| Marine-Grade Plywood | High-quality hardwood | Low-Moderate | Varies and can include sustainable sourcing | Higher, due to adhesives and source |

| Pressure-Treated Plywood | Various woods | Moderate | Chemical treatments raise concerns | Higher, due to chemical treatments |

| WBP Plywood | Hardwood, softwood | Moderate | Depends on glue and source sustainability | Moderate-High, similar to Marine-grade |

| Shuttering Plywood | Various woods | High | Reusability in formwork | Moderate reuse reduces the impact |

As I consider the materials available in my quest for sustainable building, I see that our choices can leave a greener mark on the world. Whether it’s the renewable aspects of OSB plywood or the eco-friendly advancements in plywood manufacturing. Each step towards a sustainable construction model helps reduce our collective environmental impact—a testament to humankind’s ingenuity and care for the natural world.

Strength and Weight: How They Influence Roofing Choices

When assessing my options for roofing materials and the different materials options, I spotlight two crucial factors: strength and weight. These properties are incredibly influential in determining my roofing choices. Whether looking for the best roofing plywood, considering OSB for a roof replacement, or seeking wood boards capable of bearing heavy loads.

While plywood and OSB are well-suited for roofing due to their strength, they differ significantly in weight. A critical aspect in the architectural design and practical execution of a building project.

Take OSB, for instance; it’s generally heftier than its counterpart plywood. This added weight means that the process could be more laborious during installation. Impacting the swiftness of work and requiring robust structural support from the rafters and trusses.

On the flip side, plywood sheet options are lighter, which not only aids in a more streamlined installation but can also be kinder on the backs of tradespeople working at heights.

| Material | Strength | Weight | Installation Ease | Support Requirements |

|---|---|---|---|---|

| OSB | High | Moderate | Easy | Moderate |

| CDX Plywood | High | Moderate | Easy | Moderate |

| Marine-Grade Plywood | Very High | Heavy | Moderate | Low |

| Pressure-Treated Plywood | High | Heavy | Moderate | Moderate |

| WBP Plywood | High | Moderate | Easy | Moderate |

| Shuttering Plywood | High | Moderate to Heavy | Moderate | High |

Opting for the best plywood for a specific project becomes a balancing act where strength and weight play a pivotal role. If a construction is designed to support heavy loads—for example, in commercial buildings or areas prone to heavy snow—then OSB, with its excellent load-bearing capability, would likely be my go-to choice despite its weight.

In contrast, I might prefer plywood sheeting for residential projects where the balance may tilt towards ease of installation and less hefty structural demands.

Before You Go

In closing, the journey towards selecting the best roofing plywood is subtle, and there is no one-size-fits-all solution. Whether the project is a family home on residential roofs, a commercial property, or a complex architectural endeavour, the decision must be based on a detailed comparison of all available options. Through the lens of our thorough discourse, plywood emerges as a stable contender for temporary moisture resistance. In contrast, OSB distinguishes itself as a sustainable and economical sheathing alternative, especially important for new roof considerations.

Once you’ve got a good understanding, it’s a good idea to weigh up the pros and cons. A roofing contractor’s advice, coupled with an informed decision-making process, elevates the outcome of your roofing system and choosing the right plywood or even Corrugated metal roof (We’ll get onto that another time).

To ensure the success of this significant venture, a holistic view containing durability, structural integrity, and environmental considerations is indispensable. Hence, drawing upon both the composite evaluations outlined and practical advice, you can rest assured that the chosen material aligns with the project’s aspirations and intended longevity.

This is a collaborative article.